Development of measuring protocol for gas and volatile analysis of drill cuttings

Abstract

Fluid inclusions trapped in drill cores and cuttings may provide essential information about the ancient fluid system. Information can be obtained about the chemical composition and the vertical dimensions of the fluid system as well as the paleo-fluid contacts by analysing the gas and volatile compounds of those trapped fluid remnants. Logging the extracted gas and volatile compounds over drill section we can represent the profile of hydrocarbon, non-hydrocarbon and further derived parameters. A gas-analyser was built at the Department of Mineralogy, Geochemistry and Petrology, University of Szeged for analysing fluid inclusions by mechanical decrepitation in a low-pressure and high-temperature crushing chamber. The released compounds are analysed by a quadrupole mass spectrometer connected directly to the crushing chambers.

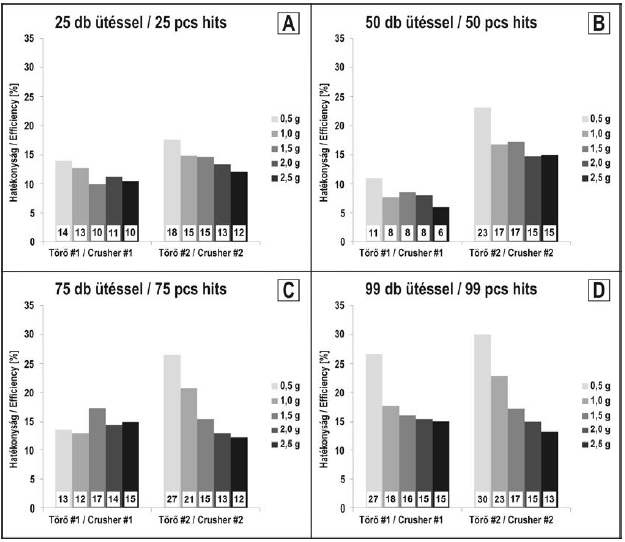

There are indispensable conditions to examine drill cuttings, such as the sample preparation and the crushing procedure for decrepitating the fluid inclusions at high efficiency. For the reproducible, representative and optimal measurement protocol we performed crushing tests on pre-sieved quartz sand and cleaning tests on pre-contaminated quartz sand. According to the results of crushing tests the amount of sample, hits rate and squeezing time, all modify the crushing efficiency but at different ways. Based on our experiments, in order to mechanically decrepitate fluid inclusions at the highest efficiency 0.5–1.0 g amount of sample, at least 50 hits and 1 sec squeezing time must be applied.

Comparing the efficiencies of different cleaning procedures it was verified that cleaning of the highly-contaminated drill cuttings with detergent is necessary to get representative analytical results. However, this cleaning procedure significantly rises the duration of sample preparation and hence the measuring time of the individual samples.

Based on the results of tests performed we have developed a measurement protocol for gas analysis of drill cores and cuttings, furthermore have marked out directions of the potential developments.